Dual Function Materials’ Value for a Greener Future

Along with efforts to reduce greenhouse gases come those to mitigate the CO2 already in the atmosphere due to human activity. This effort manifests as technologies for carbon capture utilization (CCU) that can pull waste CO2 out of industrial waste and store it. CCU can capture and use carbon directly (without chemical alteration) or indirectly (transformed) into various products. In total, carbon capture technologies make use of 230 megatonnes of CO2 per year. This phenomenon is primarily accounted for (130 megatonnes) by urea manufacturing for fertilizer and enhanced oil recovery (80 megatonnes).

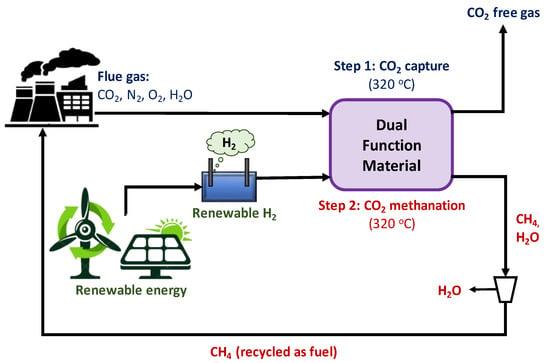

Dual Function Materials (DFMs) offer a solution to help with the remaining 20 megatonnes of captured CO2 per year. This material category can be employed to adsorb CO2 from the atmosphere and then catalyze the production of another chemical using that CO2 when induced. This process can yield a litany of valuable organic compounds such as syngas, methanol, and methane.

Related Article: The World of ESG: Standards and their Organizations

The absorption is done using the impregnation of calcium salts on a substrate of Al2O3 with a very high surface area. When absorbing CO2 from industrial gas, the industrial gas is run through the substrate. The hot CO2 reacts with the CaO salt to chemically absorb the CO2 that can later be released by heating the substrate to a lower temperature than the temperature to break the bonds of CaO.

The second step is methanation, also known as the Sabatier reaction.

CO2 + 4H2 ⇌ CH4 + 2H2O, ΔH 298Κ = −164 kJ/mol

This operation allows the CO2 from industrial processes to form into more energetic molecules, which can be used later. This conversion allows pollutants like industrial flue gases to be kept out of the atmosphere and put towards powering society.

This technology is used at around 35 commercial facilities as of 2021 and applied to industrial processes, fuel transformation, and power generation, with around 300 projects in various stages of development across the CCU’s value chain. Along with the projected increase in the number of CCU projects, the last few years have seen a marked increase in investment in this field.

A large number of the operating and projected CCU facilities are in Europe and North America, with the Chilean HIF company representing Latin America.

The United States is host to companies like Twelve, CarbonCure, and Solidia technologies that make plastics and fuels (efuels) out of the carbon they pull from the atmosphere and industrial gas. Much like their US counterparts, many European countries have their own private firms, like Germany´s North-C-Methanol and the Swiss Synhelion.

Despite Brazil not having an active indirect carbon capture and use organization working with local industry, it has a definite economic niche. Brazil has a technological base to make use of the research in the field of DFMs.

In particular, the green practice of biofuels is incredibly popular in Brazil and uses sugar-derived ethanol. All domestically made vehicles are Flexible Fuel Vehicles (FFVs) and can run off of either ethanol or methanol and gasoline mixtures. As such, the nation has a lot of synergy with the methanol-producing DFM increasingly described in academic works.

The implementation of DFM technology is fairly recent and has a lot of room to grow. Academic research and startup companies worldwide are coming around to the added efficiency this technology can offer the industry.

©www.geneonline.com All rights reserved. Collaborate with us: service@geneonlineasia.com