Distilled Truth: Bioethanol to Reduce Fossil Fuel Dependency

The recent oil price fluctuations have highlighted the increasingly clear disadvantages of sourcing the most common fuel source on earth from wells in the ground. Rather than having a predictable supply from a known source entirely produced and monitored by skilled professionals, petroleum has much more in common with coal mining than with manufacturing or agriculture. This characteristic, along with the environmental and national security concerns of petroleum dependence, contributes to the rise of biofuel usage worldwide.

A Case for Adopting Bioethanol in Modern Society

In simplest terms, biofuels are sources of chemical energy that are derived from biological sources. Most commonly, this term refers to both bio-derived ethanol and diesel but also covers more unusual sources of energy like the hydrothermal carbonization process.

Biofuels typically fall into either the ethanol or diesel category and into one of three total generations based on their source (feedstock).

|

Generation |

Description |

Examples |

|

1 |

Sugar and oil-producing crops |

Corn, sugar cane, palm oil, cassava, sugar beets, soy |

|

2 |

Agricultural waste, lignocellulosic material, waste oils |

Hydrotreated vegetable oil, wood chips, corn stover, grass |

|

3 |

Fuel crops that don’t compete with food crops at all for land or water |

Macro, and microalgae |

The successive generations of biofuels require fewer competitive inputs, making the transition from fossil fuels an easier proposition. In addition to a stable supply that can control fluctuations often seen due to oil exploration, second-generation biofuels offer the benefit of monetizing waste products and making a more efficient economy.

In the case of ethanol-based biofuels, the process begins with a carbohydrate-rich feedstock that can be converted to ethanol in a similar way to the centuries-old process of brewing and distillation. In the case of first-generation biofuels, the process of fuel production could be a possible second career for an employee of an alcohol distillery.

This same process holds its basic form with second-generation (lignocellulosic) bioethanol. Lignocellulosic bioethanol has the benefit of being made from the cellulose and hemicellulose found in wood and other inedible parts of plants. This process begins with mechanical grinding and enzyme treatment to remove the lignin from biomass from potential sources outlined in the following table:

|

Biomass |

Cellulose (%) |

Hemicellulose (%) |

Lignin (%) |

|

Corn stover |

37.5 |

30 |

10.3 |

|

Sugarcane bagasse |

45 |

20 |

30 |

|

Grasses |

25-40 |

35-50 |

10-30 |

|

Black locus (hardwood) |

41.6 |

17.7 |

26.7 |

|

Hybrid poplar (hardwood) |

44.7 |

18.6 |

26.4 |

|

Eucalyptus (hardwood) |

49.5 |

13.1 |

27.7 |

|

Hardwood stems |

40-55 |

24-40 |

18-25 |

|

Newspaper |

40-55 |

24-40 |

18-25 |

(Zhang 2020)

This remaining cellulose and hemicellulose is then enzyme-treated to be broken down into short chains or even monomeric sugars. These sugars are then fermented into ethanol using the same methods to produce first-generation bioethanol.

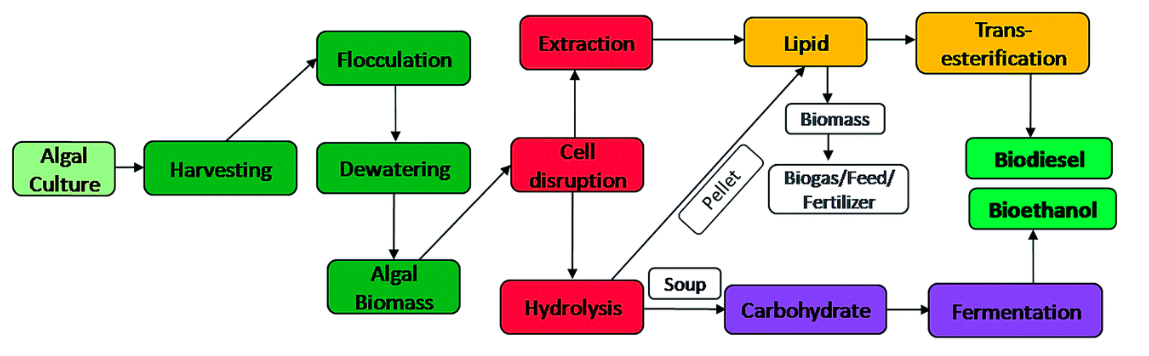

Similarly, second and third-generation bioethanol is made from carbohydrates that humans would most likely not eat. While some of the algae used in biofuel production are edible, people probably wouldn’t want to eat plant material grown in wastewater. The algae cells are lysed, and carbohydrates are separated from lipids and proteins so they may be processed into ethanol.

While bioethanol has the benefit of being relatively straightforward to produce, it is a less energetic fuel per unit volume when compared to biodiesel or other fuels with longer carbon chains.

|

Fuel |

Energy Density MJ/liter |

Notes |

|

Diesel |

37.184 |

Biodiesel is chemically the same |

|

Gasoline |

33.867 |

|

|

Ethanol |

23.278 |

Bioethanol is chemically the same |

|

Lignite coal |

12.015 |

Specific Energy and Energy Density of Fuels | Neutrium

The term ‘diesel fuel’ encompasses a larger variety of products compared to ethanol. Rather than a single chemical structure following the International Union of Pure and Applied Chemistry naming conventions, diesel is named after Rudolf Diesel and covers single-chain hydrocarbons of greater than 12 carbons in length. These longer chains offer a very energy-dense fuel that even surpasses gasoline.

This energy density flies in the face of modern batteries and raises questions regarding the eco-friendliness of electric vehicles (EVs). As much of the US still gets its electricity from coal-powered plants, EVs might pollute even more than conventional vehicles to carry less energy than a tank of diesel fuel. Electric vehicle batteries have energy density measured in watt-hours (1MJ = 277.7 WH), with the best EV batteries having between 200 and 400 WH per kilogram. Compared to the 37MJ per liter (.85kg) of diesel, the batteries are between 26 and 51 times less efficient. The technical advantage of biofuels is only compounded considering the human rights violations from lithium mining that could be avoided in a biofuel-dependent auto industry.

Biodiesel is produced from an oil-based feedstock rather than the carbohydrates that start ethanol. The fruit of the oil palm is used to make first-generation biodiesel via a transesterification reaction between the oil and methanol while second and third-generation rely on waste cooking oil and algae oil respectively.

Related article: From Food to Fuel, Are Algae the Future of Biotech?

The Planet’s Need to Develop Safer, More Efficient Biofuels

The world is responsible for producing 3,700 petajoules of biofuel per year as of 2020 with 3,212.8 petajoules of energy coming from the top ten biofuel-producing countries.

|

Country |

Petajoules |

Feedstock |

|

US |

1347.3 |

Corn, soy oil, animal fat |

|

Brazil |

883.7 |

Sugarcane, sugarcane bagasse, soy oil, animal fat |

|

Indonesia |

283 |

Palm oil, sugarcane |

|

Germany |

146.3 |

HVO, wheat, sugar beets, rapeseed oil |

|

China |

142 |

Corn, Cassava, Molasses, animal fat |

|

Thailand |

98.1 |

Palm oil, sugarcane |

|

France |

96.4 |

Wheat, sugar beets, rapeseed oil |

|

Netherlands |

83.6 |

Rapeseed oil, animal fat, palm oil |

|

Spain |

70.8 |

Palm, sunflower, soy, rapeseed oils, corn, wine pomace |

|

Argentina |

61.6 |

Soybeans, sugarcane |

Biofuel production by country 2020 | Statista

This being said, countries source their fuel differently and for different purposes. Despite the US being the largest producer of biofuel globally, it is mostly in the form of corn-based bioethanol that is used as a 10% additive to gasoline. This initially encouraging figure for bioethanol production can be deceptive, though. Unfortunately, first-generation biofuel feedstocks like corn require new land to grow a crop specifically for fuel, rather than using the materials humans can’t eat. While in the case of sugarcane, the energy density allows the biofuel to produce more energy than is required to grow the crop, corn doesn’t always have this benefit and can sometimes be a net negative to the environment and economy.

Moreover, the most efficient first-generation biofuels could still be improved. Rather than make use of valuable food crops and land, the ability for biofuel to be made from non-food is the biggest benefit of second and third-generation biofuels. HVO (hydrotreated vegetable oil) can be made from the waste made by fast-food establishments and can help the restaurant dispose of a waste product profitably rather than paying to have it disposed of responsibly.

Third-generation gets even more intricate still by making use of either photobioreactors or artificial ponds of salt or freshwater to contain the algae and ensure that it does not interfere with oceanic wildlife. These algae can be on a micro or macro (seaweed) scale and can be from the brown, red, or green algae families.

These algae are currently in the process of becoming more price efficient to produce but have yet to beat petroleum on price per barrel. As a result, many experts advise taking a “biorefinery”approach. In other words, produce a variety of products alongside algae-based biofuel for a more efficient micro-factory. This way, value can be extracted from all parts of the process, and the price of biodiesel can be lowered to a competitive level.

Besides fuel applications, algae can also produce dietary supplements, proteins for laboratory research, and fertilizer.

Third-generation biofuels still have yet to become the majority of the biofuel market and are under research and development by both private and public institutions. This being said; the arrival of these biofuels will offer the option for an energy-dense fuel that is compatible with current infrastructure. This advantage will ultimately increase accessibility to green power without the environmental destruction of battery production. Rather than drilling or mining and introducing new carbon into the atmosphere; humanity and industry is fully capable of producing a stable and clean energy source without the clear wallet pain of petroleum.

©www.geneonline.com All rights reserved. Collaborate with us: service@geneonlineasia.com